Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Help designing constant circulation with CI radiatiors and low mass boiler

Options

BBros

Member Posts: 41

Hello,

I'm in the trades and have a "reasonable" knowledge of heating systems, but need some help with specifics for a house I'm remodeling. The local heating contractors do not have much experience with the type of system I'm interested in, such as has been discussed on this site.

Home is 1920's two-story in Central Maine. Total heat-loss is around 62k btu, the largest space being kitchen/family room at 16.6k loss. Emitters are all original CI radiators, mostly 2x over-sized (i.e. bedrooms have 4.5k btu loss with over 8k in emitter capability).

I'm planning to home-run with 1/2 pex to a radiant style manifold. Boiler is Purepro Trio low-mass oil fired at 79k net IBR (smallest model). I have a hydrostat with outdoor reset capability. My intent is to have a single variable speed circulator and TRVs.

So... which circulator, which TRVs, and what else is necessary? My calculations say 145F water and perhaps only 1gpm, which seems really low. Do I need to worry about protecting the boiler from condensing, and if so, through what method.

DHW is planned to be on a separate system, but if it would be better to do a indirect to keep the mass up, I'll consider it. Do I need a pressure bypass in the system? Should it be primary-secondary? Hydronic separator?

I've read so many threads on here about various systems, and I understand most of it, but some specific layout/equipment info is still needed. My heating contractor is comfortable building whatever I want, but as noted, doesn't have familiarity with this type of system (constant circ, TRVs).

Thanks for any guidance.

I'm in the trades and have a "reasonable" knowledge of heating systems, but need some help with specifics for a house I'm remodeling. The local heating contractors do not have much experience with the type of system I'm interested in, such as has been discussed on this site.

Home is 1920's two-story in Central Maine. Total heat-loss is around 62k btu, the largest space being kitchen/family room at 16.6k loss. Emitters are all original CI radiators, mostly 2x over-sized (i.e. bedrooms have 4.5k btu loss with over 8k in emitter capability).

I'm planning to home-run with 1/2 pex to a radiant style manifold. Boiler is Purepro Trio low-mass oil fired at 79k net IBR (smallest model). I have a hydrostat with outdoor reset capability. My intent is to have a single variable speed circulator and TRVs.

So... which circulator, which TRVs, and what else is necessary? My calculations say 145F water and perhaps only 1gpm, which seems really low. Do I need to worry about protecting the boiler from condensing, and if so, through what method.

DHW is planned to be on a separate system, but if it would be better to do a indirect to keep the mass up, I'll consider it. Do I need a pressure bypass in the system? Should it be primary-secondary? Hydronic separator?

I've read so many threads on here about various systems, and I understand most of it, but some specific layout/equipment info is still needed. My heating contractor is comfortable building whatever I want, but as noted, doesn't have familiarity with this type of system (constant circ, TRVs).

Thanks for any guidance.

0

Comments

-

I See

A Taco I Valve with outdoor reset, and boiler protection. Yes you have to keep return temps to boiler above 130.

You say you have reset capability on the boiler , but not whether you have the components for ODR. Primary secondary Piping, or Hydraulic seperator. Delta P circulator on radiation side of an eco vario circ, or bumble Bee variety for the TRV's after seeing what system head is if those circs will work. They should.

If you are over radiated thats great for modulating water temps. To bad its not a Modulating boiler, but I take it oil is only available fuel source.0 -

Primary Secondary

Thanks.

I have the Aquastat 3250 w/the ODR kit. How does the Taco I Valve fit into the equation? As a replacement? Does it work in conjunction?

If using primary/secondary there will be just a standard fair circulator on the prime loop, and the variable on the secondary (sized for the head of the system). That would mean no pressure relief is necessary, correct? Or should one be on the end of the manifold so that in the event all the TRVs are closed, that it has room to flow as the pump slows down. I don't know why I envisioned a single circulator system. Not really possible.

Anyone have TRV recommendations? There seem to be quite a number of options, and variances in cost.

Indeed, oil is the only option. NG is years away and is increasing in price dramatically where available. LP is an option, but the efficiency of the mod-con wouldn't over come the added expense of fuel. Coal and wood options are not appropriate for this application.0 -

ODR

The I valve R has reset capability you have that. The S series has setpoint capability. So S Series for boiler protection it has a boiler return sensor, and supply sensor.

Delta T circ would do the job on the emitter side also probably better even than delta P. Set the delta for 20* and the circ will change speed to maintain set delta as trvs close, and higher flow rates start to happen. The Bumble bees curve may not meet the system flow rates, and head though.

TRVs Danfoss, Caleffi make nice ones.

Think about boiler cycling, and buffer tank.0 -

Bumping this old thread up, because the new heat system side of the project got backlogged significantly... but I'm back at it now. I have better understanding of this stuff, but still very much amateur.

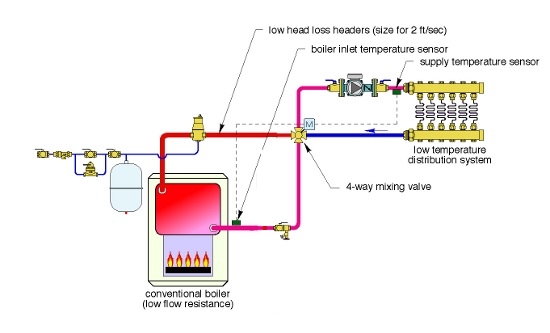

I've modified this sketch, borrowed from elsewhere, to what I'm planning on doing (deleted DHW):

Taco i-series 4-way w/ODR, and a BB or Alpha circulator. Also have some form of dirt separation, probably combo unit with air.

Hoping not to need P/S with an additional pump, but I've got to do some more calculation on the flow and head. I've also go to figure out what size 4-way, as I've read that I want to use smallest that will work, regardless of header size.

The one puzzler I have is: what happens on week+ long vacation?

With potentially 8 separate TRVs throughout the house, I'd rather not have to go into each one and turn them down. Is there a good way to add a master thermostat for full system setback? My searching through the forum hasn't produced a good answer.

0 -

For setback you could use a thermostat to control the system circulator. When the thermostat is calling all the trv's would be wide open though. In normal constant circulation mode the thermostat could be bypassed.

Or you could make an alternate reset curve and a lower temp to radiators. Effectively rendering the trv's as wide open valves again.

Depending on the equipment you choose either of those control strategies would work. The latter being the most elegant of course.

TaylorServing Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

Thanks Taylor. There doesn't seem to be a perfect solution, as you said the TRVs will be open and the balance will be off. Shouldn't be too bad, as I plan to balance at the manifold.

I think for the time being I'll go with a thermostat for ease. In an ideal world, where would this thermostat be located? I'm guessing a "cold" spot in the house?

If I'm calculating it correctly, I'll have just over 6' of head. I'm having trouble calculating because the piping will be a mix of 1/2" pex, 3/4" cu, and some 3/4 + 1" iron risers. The longest run is roughly 100' round trip with 3/4 cu risers (15' each) and the balance in 1/2" pex. However there is another run that has a significant amount of 3/4 iron, and that may offer more resistance. I haven't even considered the actual restriction of the radiator. Gulp.

Based on 65k btu, I'm looking at 6.5gpm system flow, or ~.8gpm per loop.

In another thread there was discussion about the iSeries 3/4" vs 1" in regards to Cv of 7 vs 9.3 and that it should be sized down for best response. Should I be using the 3/4? Since 6.5 is obviously closest to 7, as I understand it that's the choice. But what if I flubbed the heat-loss for the building and it's actually 7.5gpm needed... then the added head from the valve almost doubles! Would want the 1"?? I guess I don't fully understand the relationship between Cv and system flow requirements.

The boiler has 1-1/2 for supply/return, but I'm planning on bushing down immediately and piping 1-1/4" to the air scoop, then dropping to 1" to the valve (potentially down to 3/4 at the valve). On the return going from 1" back to to 1 1/4" after dirt separator. The pump and manifold piping will be 1"

Gordy mentioned the potential need for a buffer tank... I'm hoping to avoid it, but how do you determine the need?

Please point out my stupidity if it's showing. My eyes are starting to glaze over after having read so much. The idronics publications are fascinating, but overwhelming at times.0 -

So the system is up and running, but I'm getting 2 minute boiler run times, and the hydrostat isn't the most elegant solution for boiler control. Since I don't have a thermostat, I jumped T-T and that causes it to go into "boost" since it's never satisfied, so instead I've pulled the jumper and simply set the low limit to 140 (as though there were a tankless coil).

With ODR it's targeting 150 right now, given the mild 45F temp. However, as it gets colder, the low-limit will be inappropriate to supply water to the 4-way i-series (that is currently pushing 100-110F). For instance, at design of 0F, the system loop will likely require 150F water, and the hydrostat will let the primary loop temp drop to 130. So I'll have to go down and manually up the temp as the weather cools.

SO, given those two issues, I want to add a storage tank (buffer? battery?) to the mix.

Can I get a ODR controller for a tank? So that the water temp in the tank dynamic in it's temp? Then I could put the boiler on cold-start, and have it and the "primary" pump engaged by the tank controller. I've looked around a bit, but haven't seen a specific device that can do this...

Plan B at this stage is to just have the tank maintain 160 full time, as though it were an indirect, and the standby losses are probably not too great to worry about.

Plan C is to add a tank in series of the return boiler loop, but that doesn't address the odr targeting of the hydrostat, and there will be significant standby losses as it pumps past that giant heat-suck in the boiler.

For the original plan, I'm thinking of just using an old 40gal electric water heater that I have laying about. Plumb 4-way to the domestic ports and boiler to the element ports. I can use the relief valve port for a thermostat well... but what would the device actually be? I haven't found an aquastat w/ODR but maybe I'm not looking in the right place.

Thanks for all your help. Couldn't have done any of this without you.

Thoughts? @Gordy @Solid_Fuel_Man @Hatterasguy

0

Categories

- All Categories

- 86.9K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 57 Biomass

- 425 Carbon Monoxide Awareness

- 111 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 106 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 70 Pipe Deterioration

- 978 Plumbing

- 6.3K Radiant Heating

- 387 Solar

- 15.4K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 48 Job Opportunities

- 18 Recall Announcements